1. Pressed Wood Pallet Production Line In Turkiye

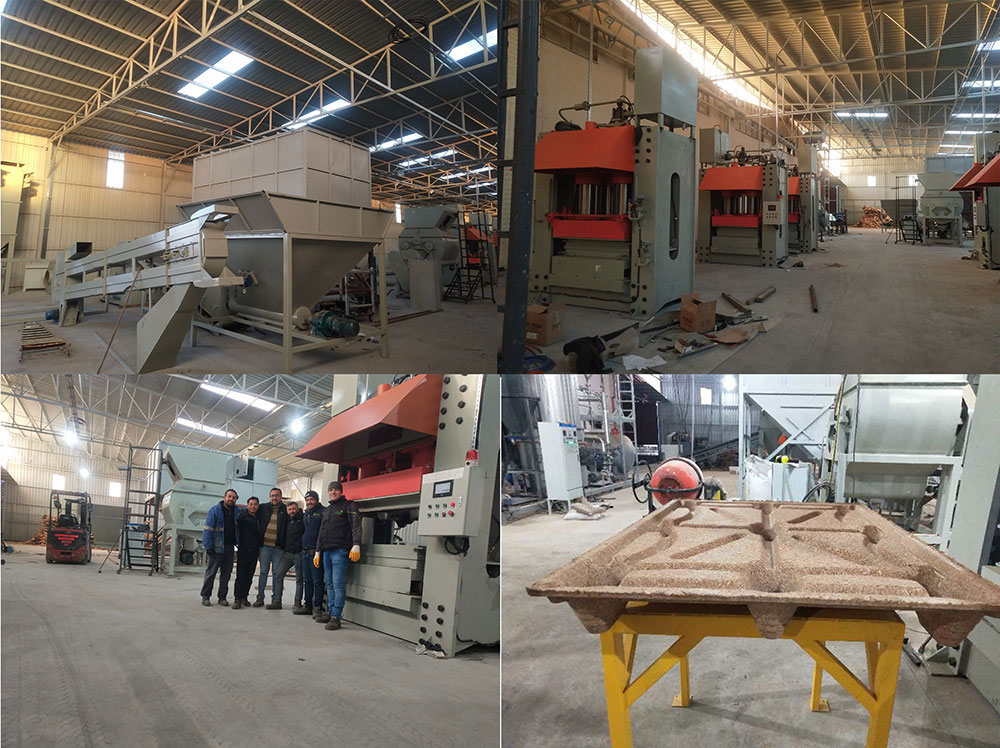

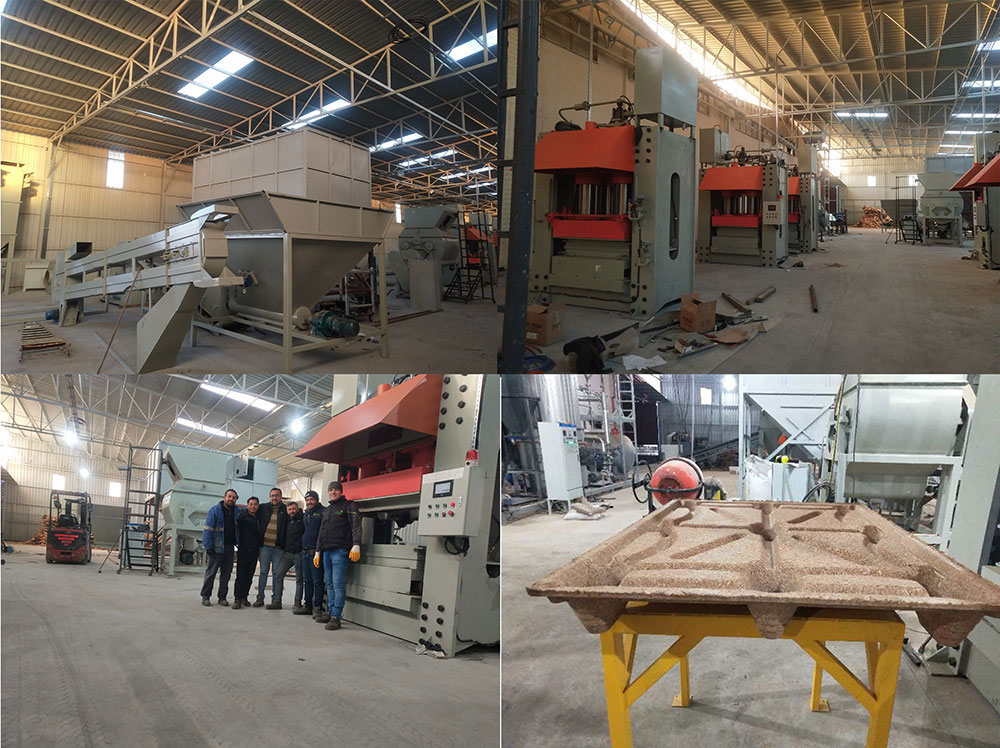

After the end of the COVID-19 crisis, we are free to travel overseas. With the assistance of our client's efforts, we can install one production line with 6 sets of press machines in Tukiye in March 2023.

The first contact was during the new year of 2023, and after 4 months of discussing, we reached an agreement. Mutual efforts will set up one complete pressed wood pallet production line.

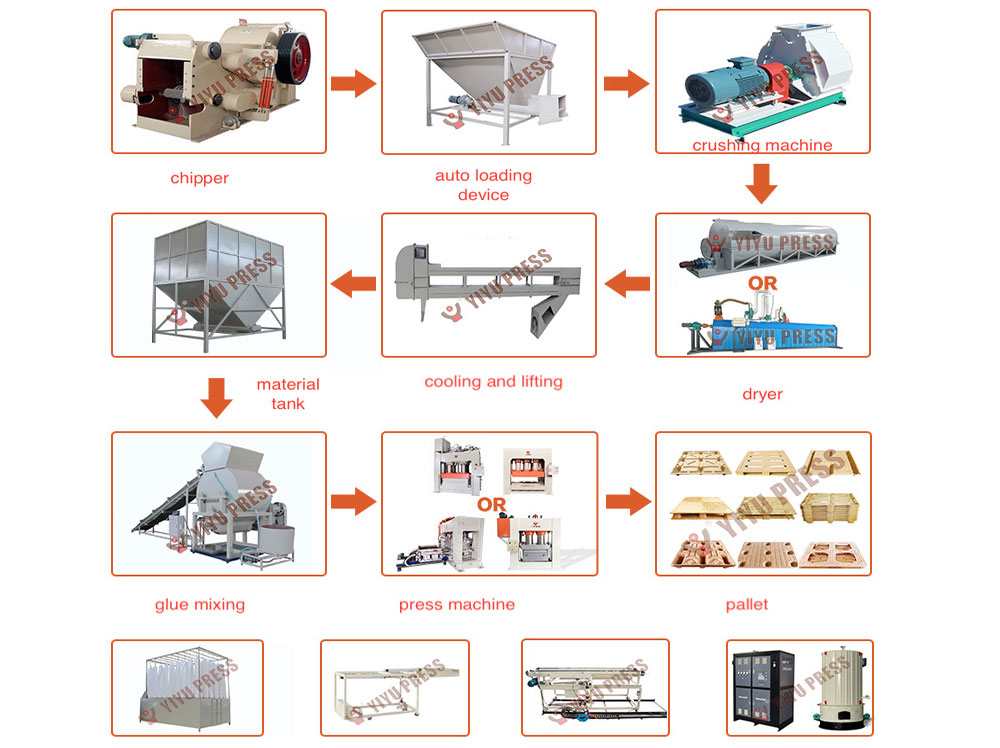

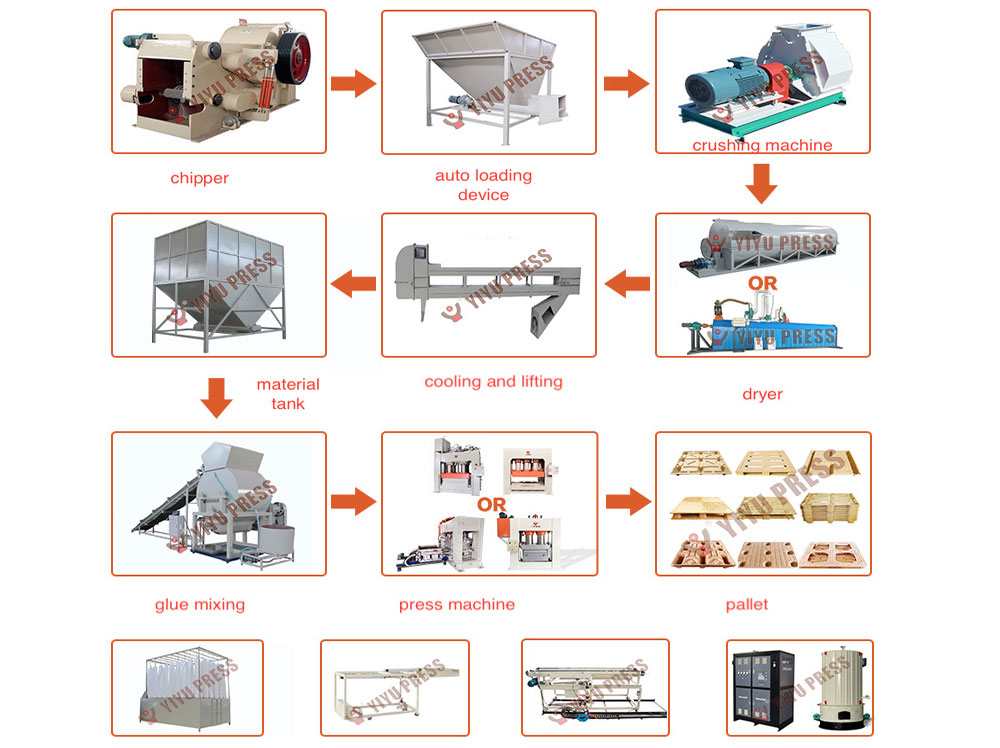

Starting from the oil boiler, wood chipper, wood crusher, dryer, and glue mixing machine to the final pallet press. We trained the workers on how to operate and maintain the machinery. Debug the small malfunctions that occurred during the production and return home successfully.

Now we are working closely with our clients, forwarding the nearby pallet request to them to expand their market. And also presenting their factory as our reference in this area for any possible visitors.

In recent inquiries from different B2B platforms, we discovered that the demand for pressed wood pallets is rising rapidly in Europe and the Middle East. Many clients are looking for pressed wood pallets now.

When the wood pallet becomes more and more expensive, pressed wood pallets appear to be the alternative choice for many companies. In China, more and more companies switched to using pressed wood pallets to transport their products. Our pressed wood pallet production line can not only help clients recycle the local wood waste material. Still, it can also increase its margins by supplying the pallet to the market.

To make a fine-pressed wood pallet, there are three key points:

- The moisture of the wood sawdust: the moisture request will be different for different glue. The most commonly used glue is urea formaldehyde glue. The wood sawdust moisture must be below 8% for this kind of glue.

- Temperature: temperature set must be suitable as per the glue curing request. Normally above 150 degrees is good.

- Ratio: wood and glue ratio is also subject to the glue type; for urea formaldehyde glue, the ratio is 80%:20%.

If you find any broken pallets or other defects in the pallets, try to adjust the above factors. You will find the right way to make a qualified pallet based on your material and local glue supplies.

There will be many difficulties in entering the pressed wood pallet manufacturing industry, with our 20 years of manufacturing experience and handling of various material types during our practices. We have our own pressed wood pallet production line next to our machinery workshop; it will help us to understand all the issues that might be happening to the machine line and how to improve it to be more easily operated and maintained. This is a unique advantage that other manufacturers do not have.

When it comes to pressed wood pallet machinery,xinyiyu molding equipment is your ideal partner world-widely. We will supply you with the best machinery and engineering service, helping you expending the market and share the latest news in the pressed wood pallet field.

If you have any wood waste recycling requests, we have a solution.

2. Automatic Operated Pressed Wood Pallet Machine Line.

When labor becomes more and more expensive in many countries. Automatic operation is in need. Developing and researching the automatic operation of pressed wood pallet machines will become our priority in 2022.

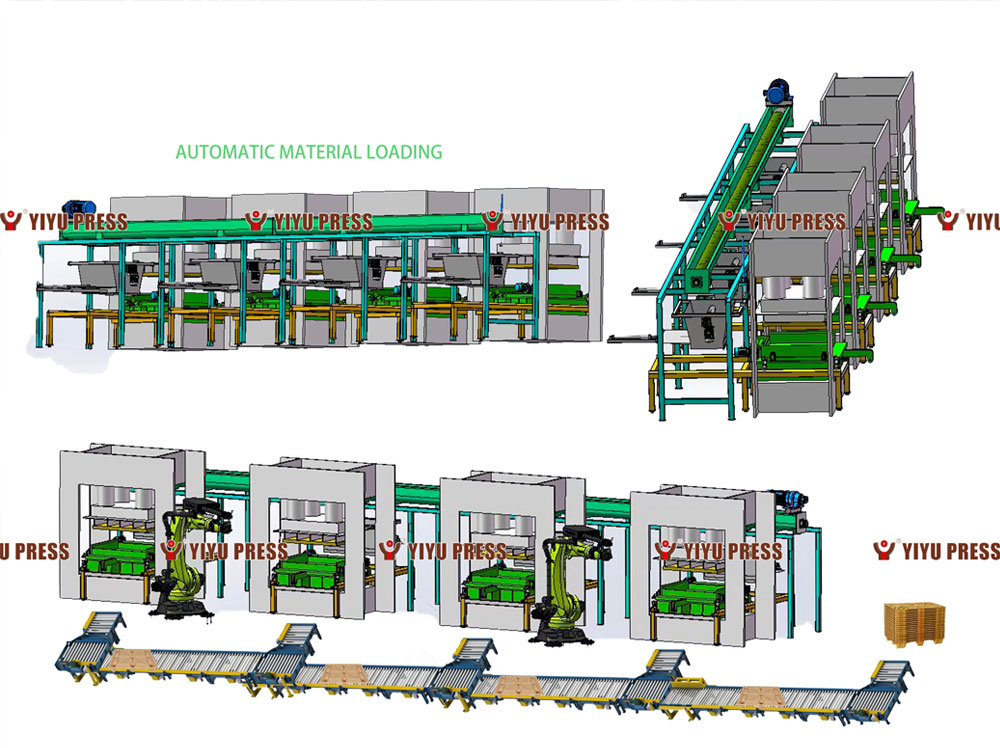

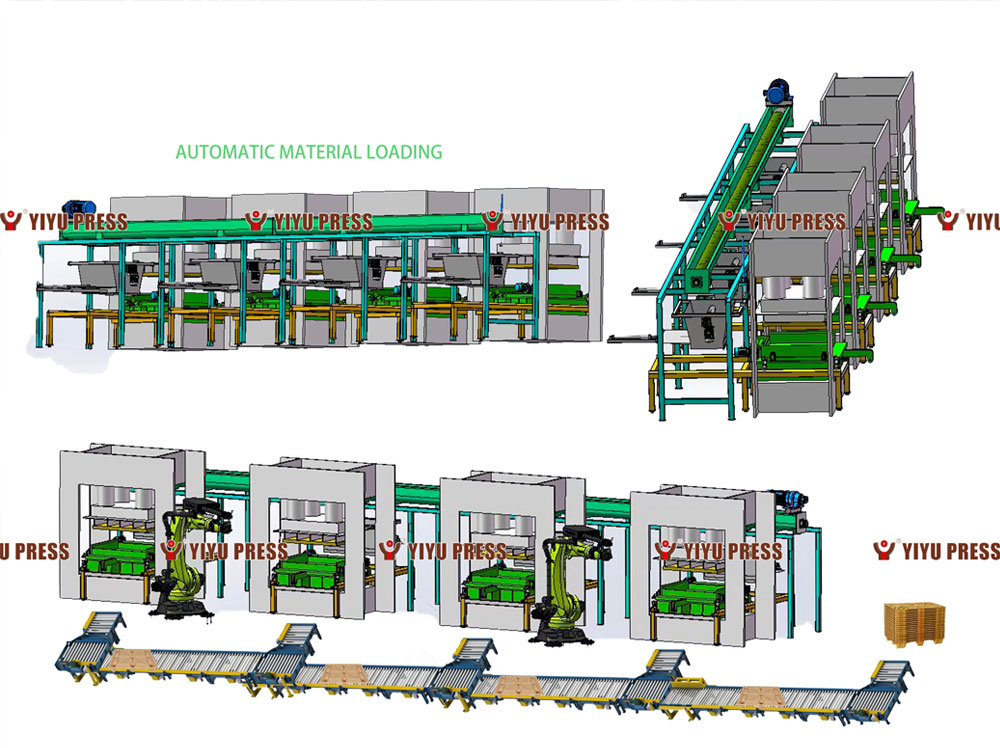

After the whole team's effort and many times to change and develop the automatic device, we have now developed two options for the automatic operation: automatic taking out by a robotic arm and another by the mechanic device. Clients can choose different devices based on the staff's combination and the workshop measurement.

Robotic arm options are more intelligent; one can handle two press machines, combine the taking out and grinding in one arm, and stack the pallets after the program is set. It can be suitable for different size pallets. Still, it will require high-level educated staff to maintain and adjust. This device required a smaller area, suitable for small-scale operation lines.

The mechanic option is easier to operate, and fewer malfunctions will appear, as it is set to remove and grind certain pallet sizes. With two sets of edges grinding knife in two directions, it is more stable, and fewer errors occur. It takes a much bigger area than the robot arm options; any operation staff can operate it by training.

Mixing automatically is also our latest development; the material is much better mixed one by one and be used as soon as possible after the mixing. With the previous design of the big mixer, sometimes the material and glue are not properly mixed in a mixing tank. The latest automatic glue mixer can be used to mix different kinds of materials and glues. The mixing quality is also better, even with small amounts, like 4% glue. The material amount and glue amount are set in the control panel. The workers only need to press the start button; after the 40s, the mixing will be done.

With the new automatic material loading and removing the device, the whole pressed wood pallet machine line can be controlled easily by trained operated staff. The loading machine will adjust the speed of the material loading from the crushing stage; after the crushing, the material will blow into the dryer and then be stored in the material tank waiting to be mixed. The material will be delivered to the automatic loading device after mixing.

Material loading is also automatic; after the mixing, the material will be conveyed to the loading device in a certain amount. The loading device will put the material into the mold to make it evenly loaded. So every corner of the pallet will have the same amount of material.

Flatting the material is very important during pressed wood pallet manufacturing. Now with the automatic loading device, it can be easily done. Making the pallets with the requested strength can withhold the heavy weight.

Talk to us about any of your pressed wood pallet machinery requests; we will provide you with a unique design based on your local condition, starting with the safest solutions and a sustainable future.

3. The Reason To Choose Pressed Wood Pallet?

Almost everywhere, you will find wood used as construction beams or decorations. Woods have helped us and elevated our taste for beauty. We need to consider other areas woods may be of great concern. And one of those areas is the environmental impact of trees.

Many people will point out the natural source of wood, but we still need to consider its impact on the planet. So, the recycling of wood materials become more and more important. This is where the pressed wood pallet machine line comes in handy.

You will get a pressed wood pallet by combining the wood material and glue and pressing it at the requested temperature.

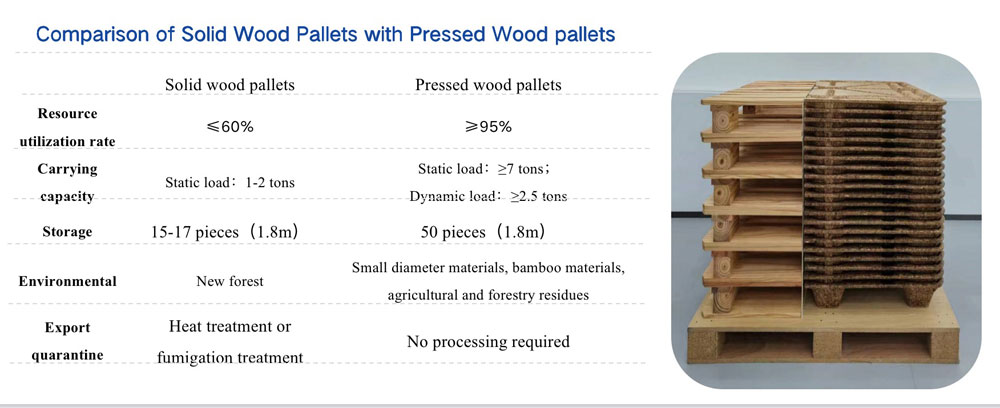

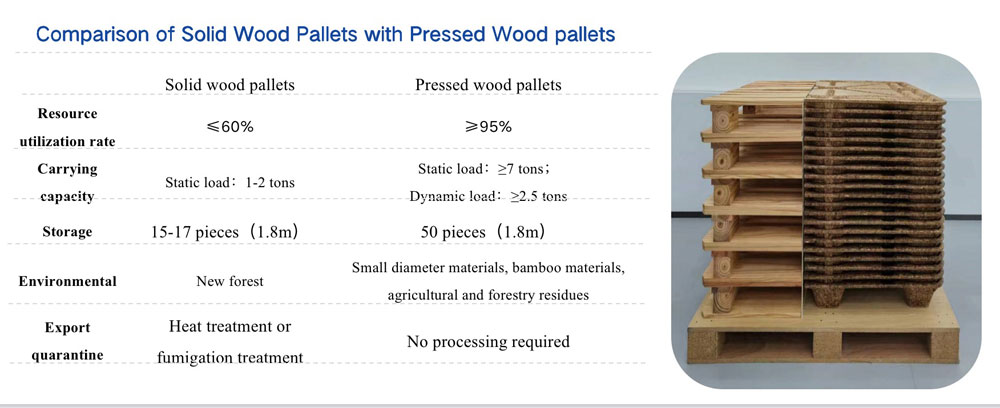

Compared with the traditional wood pallet, the advantage of the pressed wood pallet are significant:

Saving more storage space

Pallets made of pressed wood can be stacked and nested, as was already described. Manufacturers and businesses may free up valuable warehouse space by putting them in smaller stacks. In addition, by keeping more pallets on-site, businesses can maximize the space available to store goods, machinery, and other equipment.

Simple To Export

The fact that pressed wood pallets are made at such high temperatures qualifies them as processed wood. As a result, they are excluded from the rules governing ISPM15 export packaging set forth by the IPPC. They are a simple, inexpensive method of exporting goods around the globe. Thanks to the high-heat treatment, they are also free of contaminants and unwanted pests. Businesses can benefit from this by saving time and money.

Effective in terms of cost

Customers don't have to deal with the trouble or worry about additional certification procedures because the pallets are fully prepared for shipment. In the medium to long term, pressed wood pallets can also save businesses money on freight and storage. Businesses can reduce storage and freight costs by maximizing their available storage space.

Environmentally responsible

The production of pallets using pressed wood is particularly environmentally friendly. New pressed wood pallets can be made by shredding and regluing old, unusable pallets. Additionally, they are constructed from repurposed wood, all of which help businesses save money and dramatically lower their carbon footprints.

Various Weight Capacities

Pressed wood pallets can be designed and produced per different weight loading requests. Standard loading capacity is normally 1500kgs dynamically and 5000kgs statically. With special design and increased material weight, pressed wood pallets can load 2.5 tons dynamically and meet almost any special loading requirement.

Special Shape available

Sometimes it is hard to produce a round shape pallet with a wooded pallet. This is no longer a problem with pressed wood pallets. Any shape can be produced as long it is not against the forming technology. Round shape, pallet with holes on top, or other custom request shape to suit the cargo size.

More and more customers choose to use pressed wood pallets, and the market is expanding quickly. If you want to know the inside information of this industry, talk to us, and you will find all the information you need.

4. Major Pressed Wood Pallet Machinery Line Manufacturer In The World

INKA made the first pressed wood pallet in 1971 in Siegertsbrunn outside Munich, Germany. Now is a worldwide used pallet for export and cargo transportation.

The pressed wood pallet machine line manufacturers are in Germany, Italy, China, and other countries.

Dieffenbacher is one of the major players in this area; with its 150 years of experience in press systems and complete production plants for wood-based panels, they combine technologies, processes, and application know-how with extensive client collaboration to create advanced solutions to help the clients.

Imalpal in Italy is also well known pressed wood pallet production line. They have this new design of the pressed wood pallet that can use on the shelves and is also available in 4 ways entry. The whole production line can automatically run and detect the disqualified pallet while running past the detector along the conveyor.

We, Jiangxi xinyiyu molding equipment co., Ltd., collaborated cooperation from the Qingdao Yiyu group in Qingdao and Hongwei Machinery in Jiangxi, which is one of the major and leading manufacturers of pressed wood pallet machine lines. With 20 years of manufacturing experience in pressed wood pallet machinery, we set up hundreds of production lines in China and abroad.

All the machines are designed and manufactured in two workshops, starting from plate cutting, frame welding, press machine assembly, and testing before despatch. All molds are designed per the material and manufactured at the CNC center. If needed, it will be much easier to do the maintenance and repair with the whole production line.

A full package of the engineering service will be provided, including installation guidance, staff training on operation, and regular maintenance, making sure when our engineer leaves, the workers can operate the machinery and debug some minor errors by themselves.

Many hydraulic press factories sometimes produce the press wood pallet machinery as requested. The whole line is rarely supplied; one can always get the components from different suppliers. But problems will occur if those machines can not work at the same pace as designed. Therefore, after-sales service will become a huge issue for the buyers; which suppliers need to be responsible for is hard to tell. With us, it would not be a problem.

We also have one complete pressed wood pallet production line next to our machinery workshop; when you visit, you will see how a pressed wood pallet is made and how the production line is made.

Many new beginners do not know how to handle different material and glues; our years of experience comes in helpful. Wood material like wood scraps, tree branches, and logs; Agriculture waste like straws, cotton stalks, and corn stalks; bamboo waste from different industries; plastic waste like pp, pe, pet,pvc all can be used to produce different products with our pressed pallet machine.

We are also well aware of the ratio and operation notification of different types of glue. Having a good relationship with the major glue suppliers, we can recommend you to the right glue supplier suitable based on your material.

Talk to us and find out more about the material recycling.

5. Advantages of Pressed Wood Pallet

Pallets are horizontal platform devices used for assembly, stacking, handling, and transporting goods and products placed as unit loads. Pallets have been widely used in production, transportation, warehousing, and distribution as container-like transportation products. They are considered one of the two key innovations in the logistics industry in the 20th century.

The traditional wooden pallet is the ideal assistant for the turnover, circulation, temporary storage, and stacking of goods in production enterprises. It is an important logistics facility in the logistics industry. Pallets made of natural wood are the most widely used because they are cheap and strong. However, for countries with low forest occupation rates, it is possible to find new material pallets instead of wooden or bamboo pallets, which is conducive to reducing costs and helps protect forests. The pressed wood pallet is a product that mixes plant fibers with environmentally friendly synthetic resins and is molded at one time under high temperature and high pressure. The raw materials are generally recycled plant fiber materials such as waste pallets, wood waste, wooden slats, packing boxes, etc., which can be used as raw materials and loaded into the shredder for crushing. The pressed wood pallets on the market can be divided into molded concave-convex and flat trays.

Molded concave-convex trays have mature production technology abroad, represented by Inca molded concave-convex trays produced by Litco, and this product has just emerged in China in recent years. The molded flat tray is a new type of tray improved based on the concave-convex molded tray.No animal and plant inspection and quarantine, fully complies with the import quarantine system of European and American countries, and can be directly exported for use.

Its products have many unique features:

- Adopt high-tech, with plant fiber, environmental protection synthetic resin, waterproof paraffin, etc., as the main raw materials.

- High temperature and high-pressure one-time compression molding, no metal parts

- Export free of fumigation, quarantine, and visa;

- Optimized design, reasonable structure, and good overall performance;

- It meets the requirements of the world's environmental protection and can be reduced;

- Waterproof, insect-proof, termite-proof, anti-corrosion, and non-flammable;

- Strong loading capacity, not easy to deform, can be reused many times, and has a long service life;

- Four-way entry fork stacking saves space and is light in weight and beautiful in appearance.

These pressed wood pallets can also be divided into single- or double-deck pallets. The single-decked ones can use in multi-layer stacking, as their nine-leg design will break the packing of the underneath cargo. The double-decked ones will solve this problem, which is widely used in the chemical industry. Especially the sizes 1140*1140 and 1300*1100mm. The standard sizes of 1200*1000mm and 1200*800mm are widely used in the export field. Fit perfectly into the containers; no fumigation is needed, saving the exporter the time and charges for heat treatment.

Inquiries about pressed wood pallets have been increasing in recent years; big companies switched to using pressed wood pallets as a social responsibility to the planet.