- Home Page

- Company Profile

-

Our Products

- Pressed Wood Pallet Machinery

- New Design 1200tons Pressed Wood Pallet Machine in 2023

- Wood Pallet Press Machine New

- 1200 ton Wood Pallet Press Machine

- Rice Husk Pressed Pallet Making Machine Automatic Wood Sawdust Block Pallet Production Line for Sale

- China Automatic Pallet Machine Wood Bamboo Plastic Straw Fiber Pallet Press Machine

- Compressed Wood Presswood Pallet Suppliers Molding Pressing Pallet for Sale

- Hot pressed wood chips wood pallet making machine coconut fiber wood pallet press

- Automatic Compressed Wood Pallet Molding Machine Hydraulic Sawdust Wood Pallet Making Machine

- Pressed Plastic Pallet Machinery

- Cable Reel Machinery

- Pallet Block Machinery

- Auxiliary Equipment

- Air Flow Dryer

- Industrial Wood Chipper Machine

- Tube Bundle Dryer

- Wood Chipper Machine

- Wood Crusher Machine

- Automatic Mixer Machine

- Rotate Dryer

- Material Storage Tank

- Vertical Superfine Wood Powder Machine

- Vacuum dryer - biomass wood chips/straw, efficient and energy-saving

- Electric heating dryer

- Continuous dryer

- Coal-fired dryer

- Tumble dryer

- Wood chip woodworking machinery fully automatic molded wood pallet heat press

- Wooden Pallet Making Machine/High Quality Sawdust Heat Press/Pallet Making Machine

- Durable Compressed Wood Pallet Molding Machine Hydraulic Wood Pallet Machine

- High-pressure hot pressing wood pallet forming machine/sawdust pallet press processing production line

- Compressed Wood Pallets Wood Chip Compressed Pallet for Sale

- Eco-Friendly Non-Fumigated Euro Pallet Plant Fiber With Cloth and Wood Sawdust Compressed 4-Way Entry for Logistic Transport

- Large waste wood crusher machinery woodworking machinery wood crusher wood chipper

- High quality wood cutter wood crusher paper shredder wood chipper for sale

- Wood chipper log pallet wood chipper manufacturer

- Great Price Large Capacity Wood Grinder Branch Crusher Mechanical Wood Chipper

- 3-Year Warranty Vacuum Hot Air Dryer | For Wood Chips & Chemical Powders | Energy-Saving Design

- Universal Vacuum Low-Temperature Dryer for Food/Sludge/Forage | Lifetime Technical Support

- 40% Energy Saved! Vacuum Dryer - 90kg Fuel per Ton | Material Testing Supported

- Custom Vacuum Dryer for Wood Chips & Bamboo Powder | Adjustable Daily Output

- Straw vacuum dryer-moisture-proof and mildew-proof, installation guide included

- Biomass Vacuum Dryer | <5% Moisture Content | 72-Hr Fast Delivery + Lifetime Maintenance

- Vacuum Cycle Dryer with Exposed Bearings | Easy Replacement | Multi-Purpose for Wood Chips/Chemical Powder | 1+ Year Warranty

- 3-Year Warranty! Vacuum Dryer - No Wear Parts | less than 1% Dust Rate | Material Testing Supported

- Powerful Biomass Comprehensive Crusher - Ideal for Processing Various Raw Materials in Biomass Power Plants

- High - Efficiency Biomass Crusher with Wide Raw Material Adaptability for Biomass Power Generation and Recycling

- Advanced Biomass Shredder - High Output, Easy Operation for Biomass Power Plant Feedstock Preparation

- Multifunctional Biomass Crusher - Ensuring Uniform Particle Size for Biomass Processing

- High-Torque Bolt Fastening Biomass Crusher - Durable Blade for Continuous Operation | China Machinery Exporter

- Auto-Reverse Feeding & Overload Protection Biomass Crusher - Biomass Fuel Preparation | Technical Support from China

- CE+ISO Certified 1250-600 Model Biomass Crusher - Multi-Raw Material Adaptability | China Global Supplier

- Dynamic Balance Blade Roller (G6.3) Biomass Crusher - Bamboo/Small Logs Crushing | Customized Discharge System

- Hydraulic Safety Cover & Emergency Stop Biomass Shredder - Industrial Waste Recycling | China Factory Price

- Hydraulic Safety Cover & Emergency Stop Biomass Shredder - Industrial Waste Recycling | China Factory Price

- Dual Feed Roller Biomass Crusher with Adjustable Sieve - Wood Residues/Board Scrap Processing | Leading Chinese Brand

- 5M Belt Feed & Intelligent Frequency Control Biomass Crusher - Corn Stalk/Cotton Stalk Solution | China Export Quality

- 132KW Heavy-Duty Crusher with 3 Blades - Agricultural & Forestry Waste Shredder | China OEM Supplier

- 800mm Blade Roller Biomass Crusher with Hydraulic System - Bio-Power Plant Equipment | Factory Direct from China

- CE Certified 132KW High-Efficiency Biomass Crusher - Wood/Bamboo/Straw Processing | Premium Chinese Manufacturer

- Certified Safety-10-30mm Raw Material Processing | High-Efficiency Alloy Steel Multi-functional Crusher | Bamboo/Wood/Branch Processing | Professional China Manufacturer

- Durable Promotion-1-8mm Granule High-Yield Grinder | Bamboo/Waste Processing | Factory/Rural Use | Premium Supplier

- Grounding Motor Safety-Anti-Clogging Multi-functional Crusher | Bamboo/Wood Shredding | Industrial-Grade Equipment | Direct from China Factory

- High-Efficiency-Electric Heating Industrial Dryer with Temperature Control - Chemical/Agricultural Drying Equipment - China Certified Supplier

- Variable Frequency Drive-High-Temperature Resistant Electric Dryer - Dehumidifying Fan System - Food/Industrial Material Drying - Direct from Manufacturer

- Integrated Installation-Electric Heating Drying Machine - Adjustable Thermostat - Chemical/Agricultural Material Processing - Factory Supply from China

- Heavy-Duty Design-Industrial Electric Dryer - Gear Oil & Grease Lubrication System - High-Temp Material Drying Solutions - China Verified Supplier

- Safety Insulation-Electric Heating Drying Equipment - Variable Speed Control - Chemical/Manufacturing Applications - Professional Maintenance Support

- 1-Year Warranty-Continuous Electric Heating Dryer - Auto Lubrication & Dehumidifying Fan - Food/Chemical Drying Equipment - China Factory Direct

- Triple Safety Certified-High-Efficiency Industrial Dryer - Reverse Discharge & Temperature Control - Chemical/Processing Plants - Verified Supplier

- Energy-Saving- Continuous Operation Dryer - Multi-Frequency Feeding & Preheating System - Industrial Parts/Food Drying - OEM Manufacturer

- Integrated Design-Automatic Electric Dryer - Adjustable Feet & Gear Oil Lubrication - Continuous Production Solutions - China Export Quality

- 24H Lubrication- Combustion Heating Industrial Dryer - Lifting Plates for 5-10 Min Drying - Chemical/Agricultural High-Temp Equipment - China Factory Direct

- Safety Compliant- Heavy-Duty Thermal Dryer - Integrated Installation + Grease Lubrication - Industrial Parts/Raw Material Processing - Certified Manufacturer

- High-Temp Resistant- Multi-Source Industrial Dryer - Dehumidifying Fan + Impact-Resistant Barrel - Food/Chemical Drying Systems - Export Quality from China

- Scheduled Maintenance- Burner-Driven Drying Machine - Adjustable Support Feet + Gear Oil Lubrication - Agricultural/Industrial Use - OEM Supplier in China

- [Safety Certified] [10-30mm Feed Size] Multi-Functional Crusher for Pet Shavings/Bamboo Processing - China Manufacturer

- [Durable Promotion] [1-8mm Output Granules] Wood/Branch Shredder for Pet Bedding & Agricultural Waste - Chinese Supplier

- [High-Efficiency Certified] [High-Carbon Alloy Blades] Industrial Grinder for Pet Shavings/Wood Recycling - Factory Direct China

- Paper Core Plug Making Machine

- Pallet Press Machine

- Pressed Wood Pallet Machinery

- News

- Contact Us

Pallet Press Machine

Product Details:

- Motor Power 3.7 kW

- Frame Type Welded Steel Frame

- Plastic Processed HDPE, PP

- Frequency 50/60 Hz

- Noise Level <75 dB

- Model No PPM-2200

- Production Capacity 60 Pallets/Hour

- Click to view more

X

Pallet Press Machine Price And Quantity

- 1 Unit

- Available

- 1200 x 1200 mm

- Integrated

- Emergency stop, Overload protection

- 180 L

- Touch Screen HMI

- 2450 kg

- In Stock

Pallet Press Machine Product Specifications

- HDPE, PP

- Welded Steel Frame

- 3.7 kW

- 2300 kg

- Electric

- <75 dB

- High

- 50/60 Hz

- 2200 x 1800 x 2300 mm

- Water Cooled

- Heavy Duty, Precision Mould

- Automatic

- PPM-2200

- 60 Pallets/Hour

- Blue / Yellow

- Hydraulic Drive

- Ethernet, USB

- 0.05 mm

- Hydraulic

- 4.5 kW

- Automatic Lubrication

- Pallet Forming

- Pallet Press Machine

- PLC Controlled

- 220/440 V

- 0C to 45C

- Industrial pallet shaping and pressing

- Available

- 1200 x 1200 mm

- Integrated

- Emergency stop, Overload protection

- 180 L

- Touch Screen HMI

- 2450 kg

- In Stock

Pallet Press Machine Trade Information

- 10 Unit Per Month

- 20 Days

Product Description

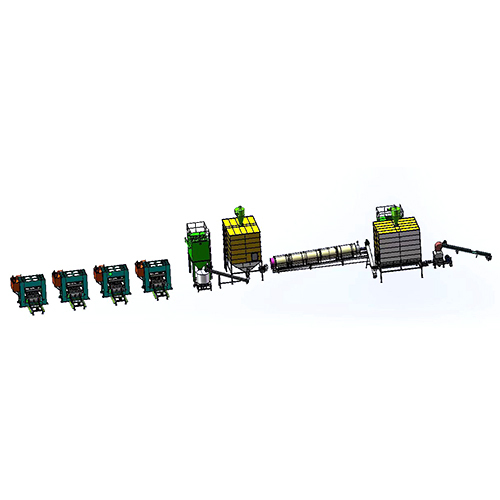

Compressed wood pallet production line:

One completed compressed wood pallet line includes press machine, wood chipper, dryer, glue mixer, storage tank etc. Our compressed wood pallet production line has been proven to be stable, high efficiency, low energy consumption, can manufacture the compressed wood pallet with higher loading capacity and reduce the defective rate to 0%.

To make a fine quality compressed wood pallet, there are three key points you must be aware of:

- Moisture of the wood sawdust working with different glues. For normal urea formaldehyde glue, the sawdust moisture must below 8%. As a result, you must use a dryer to dry the material with proper temperature and safety operation.

- Temperature: minimum 150 degree.

- Pressing time: 300-350second for urea formaldehyde.

Main machine in a compressed wood pallet line is Hot press machine. Now we have two choices for the press machine:

Single working station: one top mold with one bottom mould.

Double working station: one top mold with two movable bottom moulds.

Accessory Machinery in a compressed wood pallet line includes:

- Wood Chipping Machine: processing the wood waste material into smaller particles for further processing.

- Automatic Loading Machine Before Crushing: loading the material into the crushing machine with controlled speed.

- Wood Crushing Machine, as name as hammer mill, processing the wood particles into even small pieces within 2-50mm length, 2-5mm thickness.

- Wood dryer divided into two types by different heating method: Thermal oil/Steam heated dryer and Electronic dryer. Dry the material into requested moisture.

- Material Storage Silo for the material storage after drying.

- Glue Mixer: mixing the material with glue with a certain ratio.

Advanced Safety and Control Features

This press machine prioritizes user safety with an emergency stop and overload protection, ensuring quick response to hazardous scenarios. The PLC-controlled system and touch screen HMI provide intuitive operation and monitoring, making processes accessible and reducing human error. Automatic lubrication and water cooling enhance the machines longevity and operational reliability.

Precision and Efficiency for Industrial Applications

Engineered for high-volume industrial use, the machine achieves a precision accuracy of 0.05 mm, ensuring consistent quality in pallet formation. Its robust hydraulic system delivers high pressure and speed, with a capacity to produce up to 60 pallets per hour. Ethernet and USB connectivity options facilitate seamless data management and integration into automated production lines.

Comprehensive Support and Installation

Installation services are readily available, supported by ample spare parts in stock for minimised downtime. Whether you are a manufacturer, exporter, distributor, or trader, the machines durable build and integrated systems streamline pallet production while the suppliers support services guarantee a smooth operational experience from setup to maintenance.

FAQs of Pallet Press Machine:

Q: How does the emergency stop feature enhance operator safety on the Pallet Press Machine?

A: The emergency stop allows operators to immediately halt machine operations in case of potential danger, helping to prevent accidents and reduce risks during pallet pressing processes.Q: What is the maximum size of pallet that can be formed with this machine?

A: The machine is designed to create pallets up to 1200 x 1200 mm, making it suitable for standard industrial applications where large and sturdy pallets are required.Q: Where is the machine typically installed and can installation services be provided?

A: The Pallet Press Machine is suited for industrial sites like manufacturing plants and warehouses. Professional installation services are available to ensure proper setup and integration into your facility.Q: When are spare parts typically required, and are they readily available?

A: Spare parts are generally needed during routine maintenance or after extended operation. The supplier maintains an inventory of spare parts in stock, ensuring quick replacements and reduced downtime.Q: What materials can be processed with this pallet press machine?

A: This equipment efficiently processes HDPE and PP materials, providing versatility for different types of industrial pallets and packaging needs.Q: How does the integrated heating and cooling system benefit the pallet forming process?

A: The heating system ensures optimal material molding while the water cooled technology prevents overheating, resulting in consistent pallet quality and extended machine life during continuous operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email